高密封雙向硬密封蝶閥的長壽秘訣

Longevity secret of high sealing bidirectional hard sealing butterfly valve

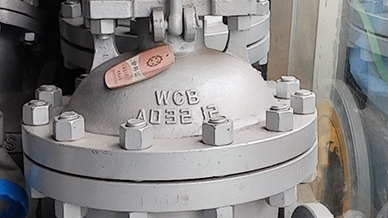

蝶閥,溝槽蝶閥目前,蝶閥作為一種用來實(shí)現(xiàn)管路系統(tǒng)通斷及流量控制的部件,已在石油、化工、冶金、水電等許多領(lǐng)域中非常廣泛地應(yīng)用。在已公知的蝶閥技術(shù)中,其密封形式多采用密封結(jié)構(gòu),密封材料為橡膠、聚四等。由于結(jié)構(gòu)特征的限制,不適應(yīng)、高壓及、抗磨損等行業(yè)。現(xiàn)有一種比較的蝶閥是三偏心金屬硬密封蝶閥,閥體和閥座為連體構(gòu)件,閥座密封表面層堆焊耐溫、耐蝕合金材料。多層軟疊式密封圈固定在閥板上,這種蝶閥與傳統(tǒng)蝶閥相比具有,操作輕便,啟閉無磨擦,關(guān)閉時(shí)隨著傳動(dòng)機(jī)構(gòu)的力矩加大來補(bǔ)償密封,消防溝槽蝶閥,提高了蝶閥的密封性能及延長使用壽命的優(yōu)點(diǎn)。但是,這種蝶閥在使用過程中仍然存在以下問題:

Butterfly valve, grooved butterfly valve at present, as a component used to realize the on-off and flow control of pipeline system, butterfly valve has been widely used in many fields such as petroleum, chemical industry, metallurgy, hydropower and so on. In the well-known butterfly valve technology, its sealing form mostly adopts sealing structure, and the sealing materials are rubber, POLY-4, etc. Due to the limitation of structural characteristics, it is not suitable for, high pressure and anti-wear industries. The existing butterfly valve is a three eccentric metal hard sealing butterfly valve. The valve body and valve seat are connected components, and the sealing surface of the valve seat is overlaid with temperature resistant and corrosion-resistant alloy materials. The multi-layer soft laminated sealing ring is fixed on the valve plate. Compared with the traditional butterfly valve, this butterfly valve has the advantages of light operation, no friction in opening and closing, compensation for sealing with the increase of the torque of the transmission mechanism when closing, and fire-fighting groove butterfly valve, which improves the sealing performance and prolongs the service life of the butterfly valve. However, the following problems still exist in the use of this butterfly valve:

一、由于多層軟硬疊式密封圈固定在閥板上,當(dāng)閥板常開狀態(tài)時(shí)介質(zhì)對(duì)其密封面形成正面沖刷,金屬片夾層中的軟密封帶受沖刷后,直接影響密封性能。

1、 As the multi-layer soft and hard laminated sealing ring is fixed on the valve plate, when the valve plate is normally open, the medium forms a positive scouring on its sealing surface, and the soft sealing belt in the metal sheet interlayer will directly affect the sealing performance after being scoured.

二、受結(jié)構(gòu)條件的限制該結(jié)構(gòu)不適應(yīng)做通徑DN200以下閥門,原因是閥板整體結(jié)構(gòu)太厚,流阻大。

2、 Limited by structural conditions, the structure is not suitable for valves with a diameter below DN200, because the overall structure of the valve plate is too thick and the flow resistance is large.

三、因三偏心結(jié)構(gòu)的原理,閥板的密封面與閥座之間的密封是靠傳動(dòng)裝置的力矩使閥板壓向閥座。正流狀態(tài)時(shí),介質(zhì)壓力越高密封擠壓越緊。當(dāng)流道介質(zhì)逆流時(shí)隨著介質(zhì)壓力的加大閥板與閥座之間的單位正壓力小于介質(zhì)壓強(qiáng)時(shí),密封開始泄漏。

3、 Due to the principle of three eccentric structure, the sealing between the sealing surface of the valve plate and the valve seat is pressed against the valve seat by the torque of the transmission device. In the normal flow state, the higher the medium pressure, the tighter the seal extrusion. When the medium in the flow channel flows backward, with the increase of medium pressure, when the unit positive pressure between the valve plate and the valve seat is less than the medium pressure, the seal begins to leak.

高性能三偏心雙向硬密封蝶閥,其特征在于:所述閥座密封圈由軟性T形密封環(huán)兩側(cè)多層不銹鋼片組成。閥板與閥座的密封面為斜圓錐結(jié)構(gòu),在閥板斜圓錐表面堆焊耐溫、耐蝕合金材料;固定在調(diào)節(jié)環(huán)壓板之間的彈簧與壓板上調(diào)節(jié)螺栓裝配一起的結(jié)構(gòu)。這種結(jié)構(gòu)地補(bǔ)償了軸軸套與閥體之間的公差帶及閥桿在介質(zhì)壓力下的彈性變形,解決了閥門在雙向互換的介質(zhì)輸送過程中存在的密封問題。

The high-performance three eccentric two-way hard sealing butterfly valve is characterized in that the valve seat sealing ring is composed of multi-layer stainless steel sheets on both sides of the soft T-shaped sealing ring. The sealing surface of valve plate and valve seat is inclined conical structure, and the inclined conical surface of valve plate is overlaid with temperature resistant and corrosion-resistant alloy materials; The spring fixed between the adjusting ring pressing plate and the adjusting bolt on the pressing plate are assembled together. This structure compensates the tolerance zone between the shaft sleeve and the valve body and the elastic deformation of the valve stem under medium pressure, and solves the sealing problem of the valve in the process of two-way interchangeable medium transmission.

采用軟性T型兩側(cè)多層不銹鋼片組成密封圈,具有金屬硬密封和軟密封的雙重優(yōu)點(diǎn),無論在低溫和高溫情況下,均具有零滲漏的密封性能

The soft T-shaped multi-layer stainless steel sheets on both sides are used to form the sealing ring, which has the dual advantages of metal hard seal and soft seal. It has zero leakage sealing performance under low and high temperature

The above is the detailed introduction of Shanghai Lianggong valve. I hope it will help you If you have any questions, please contact us We will provide you with professional service http://www.szgotta.com.cn

企業(yè)公告:

企業(yè)公告: