隨著閥門技術的不斷發展,閥門應用領域的不斷拓寬,與之對應的閥門標準也越來越不可或缺。

With the continuous development of valve technology and the continuous expansion of valve application fields, the corresponding valve standards are becoming increasingly indispensable.

球閥是良工閥門產品中眾多產品之一,那么球閥在安裝的過程中需要注意以下

Ball valve is one of many products of Lianggong valve, so the following should be paid attention to during the installation of ball valve

問題,以避免造成不必要的損失。

Problems to avoid unnecessary losses.

1、安裝前的準備

1. Preparation before installation

⑴球閥前后管線已準備好。前后管道應同軸,兩法蘭密封面應平行。管道應能承受球閥的重量,否則管道上需要配有適當的支撐。

⑴ the front and rear pipelines of the ball valve are ready. The front and rear pipes shall be coaxial, and the sealing surfaces of the two flanges shall be parallel. The pipeline should be able to bear the weight of the ball valve, otherwise the pipeline needs to be equipped with appropriate support.

⑵把閥前后管線吹掃干凈,清除掉管道內的油污、焊渣和一切其它雜質。

(2) purge the pipelines before and after the valve, and remove the oil, welding slag and all other impurities in the pipeline.

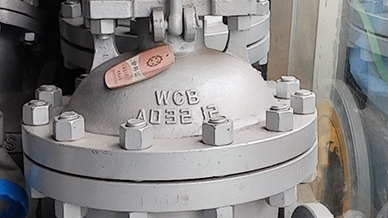

⑶核對球閥的標志查明球閥完好無損。將閥全開全閉數次證實其工作正常。

(3) check the mark of the ball valve to make sure it is intact. Fully open and close the valve for several times to confirm its normal operation.

⑷拆去球閥兩端連接法蘭上的保護件。

(4) remove the protective parts on the connecting flanges at both ends of the ball valve.

⑸檢查閥孔清除可能有的污物,然后清洗閥孔。閥座與球之間即使僅有微小顆粒的異物也可能會損傷閥座密封面。

(5) check the valve hole, remove the possible dirt, and then clean the valve hole. Even small particles of foreign matter between the valve seat and the ball may damage the sealing surface of the valve seat.

2、開始安裝球閥

2. Start installing ball valve

⑴把閥裝上管線。閥的任何一端都可裝在上游端。用手柄驅動的閥可安裝在管道上的任意位置。但帶有齒輪箱或氣動驅動器的球閥應直立安裝,即安裝在水平管道上,且驅動裝置處于管道上方。

(1) install the valve on the pipeline. Any end of the valve can be installed at the upstream end. The valve driven by the handle can be installed at any position on the pipeline. However, ball valves with gear boxes or pneumatic actuators should be installed vertically, that is, installed on horizontal pipelines, and the driving device is above the pipeline.

⑵閥法蘭與管線法蘭間按管路設計要求裝上密封墊。

(2) the sealing gasket shall be installed between the valve flange and the pipeline flange according to the pipeline design requirements.

⑶法蘭上的螺栓需對稱、逐次、均勻擰緊。

(3) the bolts on the flange shall be tightened symmetrically, step by step and evenly.

⑷連接氣動管線(采用氣動驅動器時)。

(4) connect pneumatic pipeline (when pneumatic driver is used).

3、良工球閥安裝后的檢查

3. Inspection of Lianggong ball valve after installation

⑴操作驅動器啟、閉球閥數次,應靈活無滯澀,證實其工作正常。

(1) operate the driver to open and close the ball valve for several times, which should be flexible without stagnation, and confirm that it works normally.

⑵按管路設計要求對管道與良工球閥間的法蘭結合面進行密封性能檢查。

⑵ the sealing performance of the flange joint surface between the pipeline and Lianggong ball valve shall be checked according to the pipeline design requirements.

The above is a detailed introduction about Shanghai Lianggong valve. I hope it will help you If you have any questions, please contact us We will provide you with professional service http://www.szgotta.com.cn

企業公告:

企業公告: