1、應用范圍:蒸汽管網疏水,換熱設備疏水,伴熱線疏水。

1. Scope of application: steam pipe network drainage, heat exchange equipment drainage, tracing wire drainage.

2、系統壓力和蒸汽溫度:蒸汽供應蒸汽的壓力,無論是大波動,飽和蒸汽,過熱蒸汽還是過熱考慮閥門材料的允許限度。

2. System pressure and steam temperature: the pressure of steam supply steam, whether it is large fluctuation, saturated steam, superheated steam or superheated steam, consider the allowable limit of valve material.

3、背壓和壓差:此項與疏水閥的正常排水有關。系統設計并不意味著較高的背壓更好。特別是對于大型蒸汽冷凝水系統,許多設計人員希望利用冷凝水的殘余壓力來排水。可能的殘留壓力可使冷凝水被輸送到另一個收集點。但是,它通常適得其反,使整個冷凝水排放系統變得混亂和癱瘓。

3. Back pressure and differential pressure: this item is related to the normal drainage of the drain valve. System design does not mean that higher back pressure is better. Especially for large-scale steam condensate system, many designers hope to use the residual pressure of condensate to drain. The possible residual pressure allows the condensate to be transported to another collection point. However, it usually backfires, making the whole condensate drainage system chaotic and paralyzed.

4、負荷系數:估算大和小冷凝水負荷,然后選擇適合您現場特點的系數。當用于高速熱交換器時,可以考慮使用2-3倍蒸汽消耗量的系數。另一方面,對于蒸汽管道排水,可以考慮較低的系數,并且選擇也可以直接基于管道產生的冷凝水量。主要原因是考慮到大多數當前站點排水點的合理性,絕緣材料的當前性能的改進以及蒸汽加熱管操作規范和正常要求的顯著改良。在操作過程中考慮管道冷凝物。

4. Load factor: estimate the large and small condensate load, and then select the factor suitable for your site characteristics. When used in high-speed heat exchangers, a coefficient of 2-3 times the steam consumption can be considered. On the other hand, for steam pipeline drainage, a lower coefficient can be considered, and the selection can also be directly based on the amount of condensate generated by the pipeline. The main reason is that considering the rationality of the drainage points of most current stations, the improvement of the current performance of insulating materials and the significant improvement of the operation specifications and normal requirements of steam heating pipes. Pipeline condensate shall be considered during operation.

5、設備類型:過程操作的特性和要求決定了疏水閥的主要選擇。這個項目是重要的。例如,設備在特定時間是否具有溫度控制要求,是否先加熱然后隔熱,負載前后的負荷是否顯著變化,具有熱容量(例如大儲水容量)的容積式熱交換器。帶虹吸管的加熱桶高速運行,設備是否有大風量,等等。

5. Equipment type: the characteristics and requirements of process operation determine the main selection of steam trap. This project is important. For example, whether the equipment has temperature control requirements at a specific time, whether it is heated first and then insulated, whether the load changes significantly before and after the load, and a positive displacement heat exchanger with heat capacity (such as large water storage capacity). The heating barrel with siphon runs at high speed, whether the equipment has large air volume, etc.

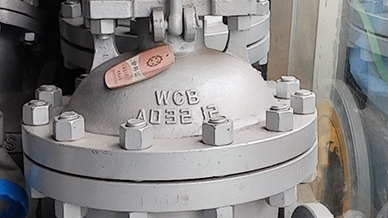

6、閥材料:不同壓力等級的系統對應于不同的閥體材料要求,例如:有很多選擇,例如球墨鑄鐵,鑄鋼,合金鋼,不銹鋼。

6. Valve material: systems with different pressure levels correspond to different valve body material requirements. For example, there are many choices, such as nodular cast iron, cast steel, alloy steel and stainless steel.

7、連接方法:考慮系統壓力和溫度要求以及用戶配置的連接方法。例如,螺絲連接,法蘭,焊接,夾具連接等。

7. Connection method: consider the system pressure and temperature requirements and the connection method configured by the user. For example, screw connection, flange, welding, clamp connection, etc.

8、工作環境:冷凍會損壞疏水閥,尤其是鑄鐵和黃銅閥門,無論閥門是否放置在溫暖的環境中。對于機械疏水閥,由于在工作過程中始終存在水封,因此需要特別注意。

8. Working environment: freezing will damage steam traps, especially cast iron and brass valves, whether the valves are placed in a warm environment or not. For mechanical traps, special attention should be paid because there is always a water seal during operation.

This article is provided for you by Lianggong valve installation. Our website is http://www.szgotta.com.cn We will wholeheartedly welcome your visit

企業公告:

企業公告: