電動固定式球閥主要使用于高壓大口徑的球閥中。是采用固定式球閥閥體和電動執行器組裝而成。根據閥座密封圈的安裝不同,固定球閥有球體前密封的閥座和球體后密封的閥座兩種結構。聚多年球閥制造經驗而設計的閥座,確保閥門密封,磨擦系數低,操作力矩小、多種閥座材料、適應范圍廣。適用于長輸管線和一般工業管線,其強度、an全性、耐惡劣環境性等在設進行了綜合考慮,適用于多種腐蝕性和非腐蝕性介質。

Electric fixed ball valve is mainly used in high-pressure large-diameter ball valve. It is assembled with fixed ball valve body and electric actuator. According to the installation of the sealing ring of the valve seat, the fixed ball valve has two structures: the valve seat sealed before the ball and the valve seat sealed after the ball. The valve seat designed with many years of ball valve manufacturing experience ensures the valve sealing, low friction coefficient, small operating torque, a variety of valve seat materials and a wide range of applications. It is applicable to long-distance pipelines and general industrial pipelines. Its strength, an integrity and resistance to harsh environment are comprehensively considered in the design. It is applicable to a variety of corrosive and non corrosive media.

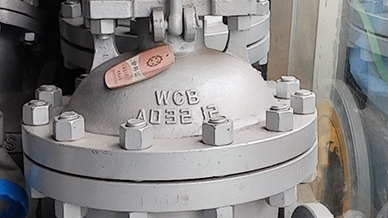

電動固定式球閥閥體采用的是高平臺結構,ISO5211連接標準。同時密封面采用的是雙向金屬可動密封結構,具有自動補償及自潔功能,密封性能好,不易磨損和耐受高溫性能更好。閥芯采用的是O型結構的全通徑或縮徑設計,流通阻力小。并增加了預緊力彈簧,使得球閥具有自動泄壓功能。

The valve body of electric fixed ball valve adopts high platform structure and ISO5211 connection standard. At the same time, the sealing surface adopts a two-way metal movable sealing structure, which has the functions of automatic compensation and self-cleaning. It has good sealing performance, not easy to wear and better resistance to high temperature. The valve core adopts the full diameter or reduced diameter design of O-shaped structure, with small flow resistance. The preload spring is added to make the ball valve have the function of automatic pressure relief.

浮動球閥的公稱通經范圍內體積較小、重量輕、材料耗用少、安裝尺寸小,并且驅動力矩小,操作簡便、易實現快速啟閉,。球體借助于閥桿可以自由地在閥座密封圈中旋轉。在開啟時,球孔與管道孔徑對準,以使管道工作介質阻力變小。當閥桿轉動1/4圈時,球孔垂直于閥門的通道,加給兩閥座密封圈的預緊力和介質壓力將球體緊緊壓在出口端的閥座密封圈上,從而使閥門密封。

The floating ball valve has the advantages of small volume, light weight, less material consumption, small installation size, small driving torque, simple operation and easy to realize rapid opening and closing,. The ball can rotate freely in the valve seat sealing ring with the help of the valve stem. When opening, the ball hole is aligned with the pipe aperture to reduce the resistance of the working medium of the pipe. When the valve rod rotates for 1 / 4 turn, the ball hole is perpendicular to the channel of the valve. The preload and medium pressure are added to the two valve seat sealing rings to tightly press the ball on the valve seat sealing ring at the outlet end, so as to seal the valve.

The wonderful contents of this article are provided by Lianggong valve agent. There are many wonderful contents on this website. You can click to enter more contents: http://www.szgotta.com.cn We have special customer service to answer your questions

企業公告:

企業公告: