選擇閥門的步驟和依據(jù)

Steps and basis for selecting valves

1選擇步驟

1 select steps

(1)明確閥門在設(shè)備或裝置中的用途,確定閥門的工作條件:適用介質(zhì)、工作壓力、工作溫度等等。

(1) Specify the purpose of the valve in the equipment or device, and determine the working conditions of the valve: applicable medium, working pressure, working temperature, etc.

(2)確定與閥門連接管道的公稱通徑和連接方式:法蘭、螺紋、焊接等。

(2) Determine the nominal diameter and connection mode of the pipeline connected with the valve: flange, thread, welding, etc.

(3)確定操作閥門的方式:手動(dòng)、電動(dòng)、電磁、氣動(dòng)或液動(dòng)、電氣聯(lián)動(dòng)或電液聯(lián)動(dòng)等。

(3) Determine the mode of valve operation: manual, electric, electromagnetic, pneumatic or hydraulic, electrical linkage or electro-hydraulic linkage, etc.

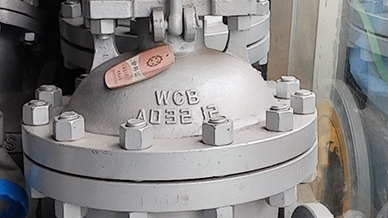

(4)根據(jù)管線輸送的介質(zhì)、工作壓力、工作溫度確定所選閥門的殼體和內(nèi)件的材料:灰鑄鐵、可鍛鑄鐵、球墨鑄鐵、碳素鋼、合金鋼、不銹耐酸鋼、銅合金等。

(4) According to the medium transported by the pipeline, working pressure and working temperature, determine the materials of the shell and internals of the selected valve: gray cast iron, malleable cast iron, nodular cast iron, carbon steel, alloy steel, stainless acid resistant steel, copper alloy, etc.

(5)選擇閥門的種類:閉路閥門、調(diào)節(jié)閥門等。

(5) Select the type of valve: closed-circuit valve, regulating valve, etc.

(6)確定閥門的型式:閘閥、截止閥、球閥、蝶閥、節(jié)流閥、減壓閥、蒸汽疏水閥等。

(6) Determine the type of valve: gate valve, globe valve, ball valve, butterfly valve, throttle valve, pressure reducing valve, steam trap, etc.

(7)確定閥門的參數(shù):對(duì)于自動(dòng)閥門,根據(jù)不同需要先確定允許流阻、排放能力、背壓等,再確定管道的公稱通徑和閥座孔的直徑。

(7) Determine the parameters of the valve: for automatic valves, the allowable flow resistance, discharge capacity, back pressure, etc. shall be determined according to different needs, and then the nominal diameter of the pipeline and the diameter of the valve seat hole shall be determined.

(8)確定所選用閥門的幾何參數(shù):結(jié)構(gòu)長(zhǎng)度、法蘭連接形式及尺寸、開啟和關(guān)閉后閥門高度方向的尺寸、連接的螺栓孔尺寸和數(shù)量、整個(gè)閥門外型尺寸等。

(8) Determine the geometric parameters of the selected valve: structural length, flange connection form and size, size of valve height direction after opening and closing, size and quantity of connected bolt holes, overall size of the whole valve, etc.

(9)利用現(xiàn)有的資料:閥門產(chǎn)品目錄、閥門產(chǎn)品樣本等選擇適當(dāng)?shù)拈y門產(chǎn)品。

(9) Use the existing data: valve product catalog, valve product samples, etc. to select appropriate valve products.

2選擇閥門的依據(jù)

2 basis for valve selection

在了解掌握選擇閥門步驟的同時(shí),還應(yīng)進(jìn)一步了解選擇閥門的依據(jù)。

While understanding and mastering the steps of valve selection, we should also further understand the basis of valve selection.

(1)所選用閥門的用途、使用工況條件和操縱控制方式。

(1) The purpose, working conditions and operation control mode of the selected valve.

(2)工作介質(zhì)的性質(zhì):工作壓力、工作溫度、腐蝕性能,是否含有固體顆粒,介質(zhì)是否有毒,是否是易燃、易爆介質(zhì),介質(zhì)的黏度等等。

(2) Properties of working medium: working pressure, working temperature, corrosion performance, whether it contains solid particles, whether the medium is toxic, whether it is flammable and explosive, viscosity of the medium, etc.

(3)對(duì)閥門流體特性的要求:流阻、排放能力、流量特性、密封等級(jí)等等。

(3) Requirements for valve fluid characteristics: flow resistance, discharge capacity, flow characteristics, sealing grade, etc.

(4)安裝尺寸和外形尺寸要求:公稱通徑、與管道的連接方式和連接尺寸、外形尺寸或重量限制等。

(4) Installation dimension and overall dimension requirements: nominal diameter, connection mode and connection dimension with pipeline, overall dimension or weight limit, etc.

(5)對(duì)閥門產(chǎn)品的可靠性、使用壽命和電動(dòng)裝置的防爆性能等的附加要求。

(5) Additional requirements for the reliability and service life of valve products and the explosion-proof performance of electric devices.

選擇閥門應(yīng)遵循的原則:

Principles for valve selection:

1、截止和開放介質(zhì)用的閥門

1. Valves for stop and open media

流道為直通式的閥門,其流阻較小,通常選擇作為截止和開放介質(zhì)用的閥門。向下閉合式閥門(截止閥、柱塞閥)由于其流道曲折,流阻比其他閥門高,故較少選用。在允許有較高流阻的場(chǎng)合,可選用閉合式閥門。

The flow passage is a straight through valve with small flow resistance. It is usually selected as the valve for cut-off and open medium. Downward closed valves (stop valve, plunger valve) are less selected because of their tortuous flow path and higher flow resistance than other valves. Where high flow resistance is allowed, closed valves can be selected.

2、控制流量用的閥門

2. Valve for controlling flow

通常選擇易于調(diào)節(jié)流量的閥門作為控制流量用。向下閉合式閥門(如截止閥)適于這一用途,因?yàn)樗拈y座尺寸與關(guān)閉件的行程之間成正比關(guān)系。旋轉(zhuǎn)式閥門(旋塞閥、蝶閥、球閥)和撓曲閥體式閥門(夾緊閥、隔膜閥)也可用于節(jié)流控制,但通常只能在有限的閥門口徑范圍內(nèi)適用。閘閥是以圓盤形閘板對(duì)圓形閥座口做橫切運(yùn)動(dòng),它只有在接近關(guān)閉位置時(shí),才能較好地控制流量,故通常不用于流量控制。

Generally, the valve easy to adjust the flow is selected as the flow control valve. Downward closing valves (such as globe valves) are suitable for this purpose because its seat size is directly proportional to the stroke of the closing member. Rotary valves (plug valves, butterfly valves, ball valves) and flex body valves (clamp valves, diaphragm valves) can also be used for throttling control, but they are usually only applicable to a limited range of valve diameters. The gate valve uses a disc-shaped gate to make a cross cutting movement to the circular valve seat. It can better control the flow only when it is close to the closed position, so it is usually not used for flow control.

3、換向分流用的閥門

3. Valve for reversing and shunting

根據(jù)換向分流的需要,這種閥門可有三個(gè)或更多的通道。旋塞閥和球閥較適用于這一目的,因此,大部分用于換向分流的閥門都選取這類閥門中的一種。但是在有些情況下,其他類型的閥門,只要把兩個(gè)或更多個(gè)閥門適當(dāng)?shù)叵嗷ミB接起來(lái),也可作換向分流用。

The valve can have three or more channels according to the needs of reversing and shunting. Plug valves and ball valves are more suitable for this purpose. Therefore, most of the valves used for directional diversion choose one of these valves. However, in some cases, other types of valves can also be used for reversing and shunting as long as two or more valves are properly connected with each other.

4、帶有懸浮顆粒的介質(zhì)用閥門

4. Valve for medium with suspended particles

當(dāng)介質(zhì)中帶有懸浮顆粒時(shí),適于采用其關(guān)閉件沿密封面的滑動(dòng)帶有擦拭作用的閥門。如果關(guān)閉件對(duì)閥座的來(lái)回運(yùn)動(dòng)是豎直的,那末就可能夾持顆粒,因此這種閥門除非密封面材料可以允許嵌入顆粒,否則只適用于基本清潔的介質(zhì)。球閥和旋塞閥在啟閉過程中對(duì)密封面均有擦拭作用,故適宜用在帶有懸浮顆粒的介質(zhì)中。

When there are suspended particles in the medium, it is suitable to use the valve with wiping function by sliding its closing part along the sealing surface. If the back and forth movement of the closing member to the valve seat is vertical, particles may be clamped. Therefore, this valve is only suitable for basically clean media unless the sealing surface material allows particles to be embedded. Ball valve and plug valve can wipe the sealing surface during opening and closing, so they are suitable for medium with suspended particles.

企業(yè)公告:

企業(yè)公告: