種類型的閥門的作用是只允許介質向一個方向流動,而且阻止方向流動。通常這種閥門是自動工作的,在一個方向流動的流體壓力作用下,閥瓣打開;流體反方向流動時,由流體壓力和閥瓣的自重合閥瓣作用于閥座,從而切斷流動。

The function of this type of valve is to allow the medium to flow in only one direction and prevent the medium from flowing in one direction. Usually, this valve works automatically. Under the action of fluid pressure flowing in one direction, the valve disc opens; When the fluid flows in the opposite direction, the fluid pressure and the self weight of the valve disc act on the valve seat, so as to cut off the flow.

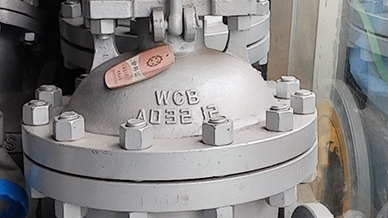

其中止回閥就屬于這種類型的閥門,它包括旋啟式止回閥和昆山良工閥門升降式止回閥。良工閥門旋啟式止回閥有一介鉸鏈機構,還有一個像門一樣的閥瓣自由地靠在傾斜的閥座表面上。

The check valve belongs to this type of valve, including swing check valve and Kunshan Lianggong valve lift check valve. The swing check valve of Lianggong valve has a medium hinge mechanism and a valve disc like a door that freely rests on the inclined seat surface.

為了確保閥瓣每次都能到達閥座面的合適位置,閥瓣設計在鉸鏈機構,以便閥瓣具有足夠有旋啟空間,并使閥瓣真正的、全面的與閥座接觸。閥瓣可以全部用金屬制成,也可以在金屬上鑲嵌皮革、橡膠、或者采用合成覆蓋面,這取決于使用性能的要求。旋啟式止回閥在完全打開的狀況下,流體壓力幾乎不受阻礙,因此通過閥門的壓力降相對較小。

In order to ensure that the valve clack can reach the appropriate position of the valve seat surface every time, the valve clack is designed in the hinge mechanism, so that the valve clack has enough swing space and makes the valve clack really and comprehensively contact with the valve seat. The valve disc can be made of metal, or inlaid with leather, rubber or synthetic coverage, depending on the requirements of service performance. When the swing check valve is fully open, the fluid pressure is almost unimpeded, so the pressure drop through the valve is relatively small.

升降式止回閥的閥瓣座落位于閥體上閥座密封面上。此閥門除了閥瓣可以自由地升降之外,其余部分如同截止閥一樣,流體壓力使閥瓣從閥座密封面上抬起,介質回流導致閥瓣回落到閥座上,并切斷流動。根據使用條件,閥瓣可以是全金屬結構,也可以是在閥瓣架上鑲嵌橡膠墊或橡膠環的形式。像截止閥一樣,流體通過升降式止回閥的通道也是狹窄的,因此通過升降式止回閥的壓力降比旋啟式止回閥大些,而且旋啟式止回閥的流量受到的限制很少。

The disc seat of the lift check valve is located on the sealing surface of the valve seat on the valve body. Except that the valve disc can rise and fall freely, the rest of the valve is like a stop valve. The fluid pressure lifts the valve disc from the sealing surface of the valve seat, and the medium backflow causes the valve disc to fall back to the valve seat and cut off the flow. According to the service conditions, the valve disc can be of all metal structure or inlaid with rubber pad or rubber ring on the valve disc frame. Like the stop valve, the passage of fluid through the lift check valve is also narrow, so the pressure drop through the lift check valve is larger than that of the swing check valve, and the flow of the swing check valve is rarely limited.

止回閥常見故障及處理方法常見故障有:

Common faults and treatment methods of check valve include:

①閥瓣打碎

① Disc broken

②介質倒流。

② Media backflow.

引起閥瓣打碎的原因是:

The causes of disc breakage are:

止回閥前后介質壓力處于接近平衡而又互相“拉鋸”的狀態,昆山良工閥門閥瓣經常與閥座拍打,某些脆性材料(如鑄鐵、黃銅等)做成的閥瓣就被打碎。預防的辦法是采用閥瓣為韌性材料的止回閥。

The medium pressure before and after the check valve is close to balance and "sawing" with each other. The valve disc of Kunshan Lianggong valve often beats the valve seat, and the valve disc made of some brittle materials (such as cast iron, brass, etc.) is broken. The way to prevent is to use the check valve with the valve disc made of ductile material.

介質倒流的原因有:

The reasons for media backflow are:

①密封面破壞

① Sealing surface damage

②夾入雜質。

② Inclusion of impurities.

修復密封面和清洗雜質,就能防止倒流。

Repairing the sealing surface and cleaning impurities can prevent backflow.

The content of this article is provided to you by Shanghai Lianggong valve. We focus on customer needs, continuous development and provide customers with more services. For details, please refer to our website http://www.szgotta.com.cn

企業公告:

企業公告: